Chemical Process Equipment Design And Drawing

Data: 2.09.2018 / Rating: 4.8 / Views: 975Gallery of Video:

Gallery of Images:

Chemical Process Equipment Design And Drawing

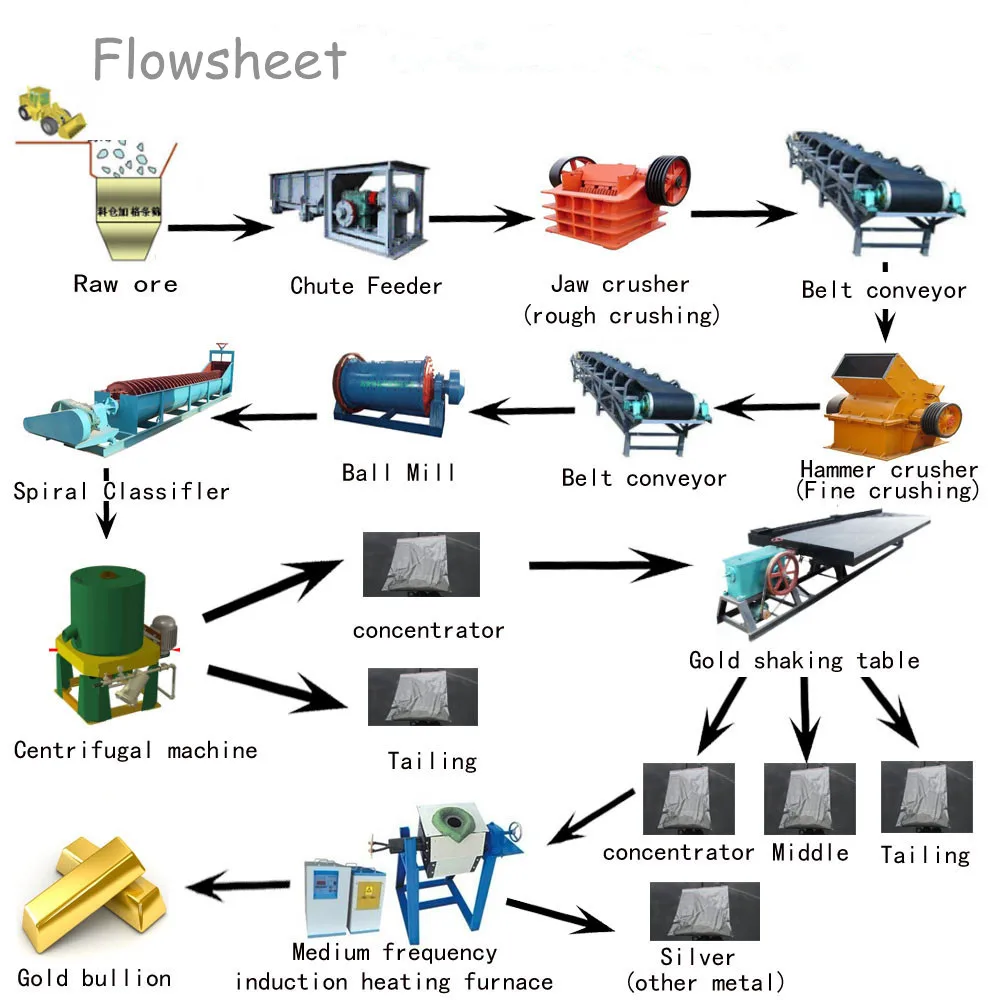

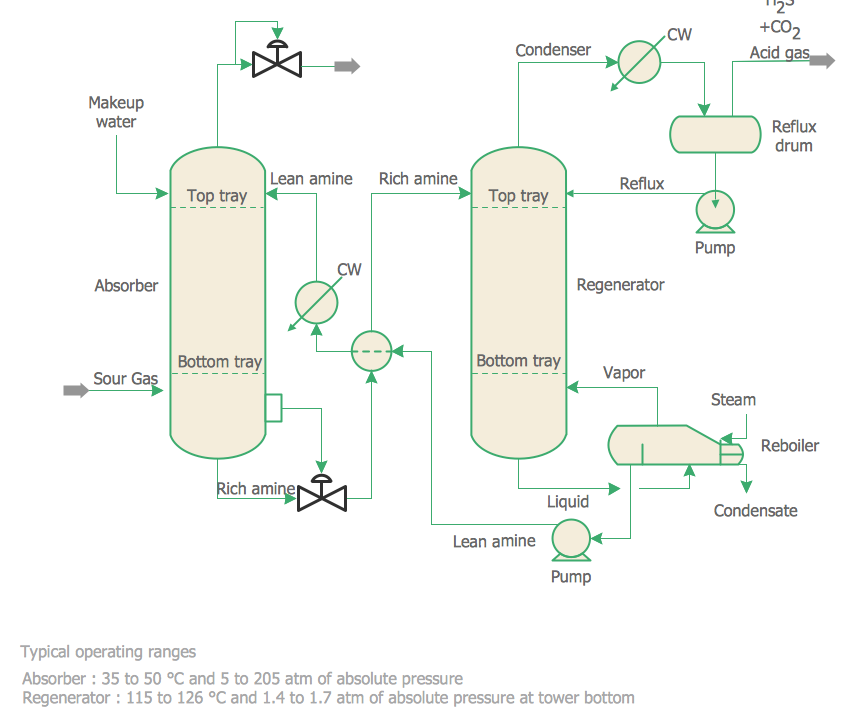

Chemical Process Equipment is a resultsoriented reference for engineers who specify, design, maintain or run chemical and process plants. This book delivers information on the selection, sizing and operation of process equipment in a format that enables quick and accurate decision making on standard process and equipment choices, saving time, improving productivity, and building understanding. The comprehensive and influential guide to the selection and design of a wide range of chemical process equipment, used by engineers globally Copious examples of successful applications, with supporting schematics and data to illustrate the functioning and performance of equipment About The Book Chemical Process Equipment Book Summary: This text introduces the students and practicing engineers to the practices and standards of drafting the equipment used in chemical, food processing, polymer engineering, and pharmaceuticals processing industries. The Concise, EasytoUse Guide to Designing Chemical Process Equipment and Evaluating Its Performance. Trends such as shalegas resource development call for a deeper understanding of chemical engineering equipment and design. It uses the symbolic representations of the equipment as used in the industry and provides the detailed drawings of some commonly used equipment. Process Equipment DesignII, Lab Manual, Chemical Engineering Department, IT, NU 2 List of Practical Expt No. Name of Practical 12 Drawing of sketches for. The example Design elements Chemical engineering was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Engineering area of ConceptDraw Solution Park. A complete overview and considerations in process equipment design. Handling and storage of large quantities of materials is crucial to the chemical engineering of a wide variety of products. The design elements example Heating equipment was created using the ConceptDraw PRO diagramming and vector drawing software extended with the Chemical and Process Engineering solution from the Engineering area of ConceptDraw Solution Park. The first step in the design process is the problem definition. This definition usually contains a listing of the product or customer requirements and specially information You can quickly draw PIDs and PFDs by dragging process engineering equipment shapes onto your drawing page, connecting them with smart pipelines, and then dragging components, such as valves and instruments, onto the pipelines. This text introduces the student to the practices and standards of making drawings for equipment used in chemical industries. The textbook follows the Bureau of Indian Standards (BIS) specifications and methodology of equipment drawings. CHEMICAL PROCESS EQUIPMENT: DESIGN AND DRAWING (VOLUME I), Second Edition, Volume 1 Ebook written by MAIDARGI, SURESH C. Read this book using Google Play Books app on your PC, android, iOS devices. Download for offline reading, highlight, bookmark or take notes while you read CHEMICAL PROCESS EQUIPMENT: DESIGN AND DRAWING (VOLUME I), Second Edition. [Design Ebook Drawing The Process. API DEVELOPMENT AND MANUFACTURE. API ScaleUp During Research and Development. Application of experimental design for process optimisation. Chemical process equipment Selection and design. Chemical process hazard analysis. FREE online Process Flow Diagram drawing template enabled for the FREE online Google Docs. Make your own Process Flow diagrams with this FREE online drawing tool. Log in to your Google Account (Google Accounts are free) and copy (File Make a copy) this online Process Flow Drawing template to start making your own drawings. Select, copy and paste the components you want to use. The process flow diagram (PFD) represents a quantum step up from the BFD in terms of the amount of information that it contains. The PFD contains the bulk of the chemical engineering data necessary for the design of a chemical process. For all of the diagrams discussed in this chapter, there are no. NPTEL provides Elearning through online Web and Video courses various streams. In chemical engineering, process design is the choice and sequencing of units for desired physical andor chemical transformation of materials. Process design is central to chemical engineering, and it can be considered to be the summit of that field, bringing together all of the field's components. Fundaments of Chemical Engineering Process Equipment Design applications of basic design engineering principles is a challenge for fresh graduates. understanding of process equipment design techniques and to build a foundation to those who are new to the design. Cheap Chemical Process Equipment: Design and Drawing, Vol. I, You can get more details about Chemical Process Equipment: Design and Drawing, Vol. com This text introduces the students and practicing engineers to the practices and standards of drafting the equipment used in chemical, food processing, polymer engineering, and. Comprehensive and practical guide to the selection and design of a wide range of chemical process equipment. Emphasis is placed on realworld process design and performance of equipment. Provides examples of successful applications, with numerous drawings, graphs, and tables to show the functioning and performance of the equipment. CHEMICAL PROCESS EQUIPMENT: DESIGN AND DRAWING Volume I by MAIDARGI SURESH C. Buy CHEMICAL PROCESS EQUIPMENT: DESIGN AND DRAWING Volume I online for Rs. Free Shipping and Cash on Delivery All Over India. Laboratory Design Handbook CONTENTS hold a lot of equipment to perform chemical analysis or ovens and heating elements to speed up chemical processes. Without an adequate supply of cool air, the laboratory housing this equipment will become uncomfortably warm. Comprehensive and practical guide to the selection and design of a wide range of chemical process equipment. Emphasis is placed on realworld process design and performance of equipment. Provides examples of successful applications, with numerous drawings, graphs, and tables to show the functioning and performance of the equipment. chemical process equipment design and drawing volume i PDF ePub Mobi Download chemical process equipment design and drawing volume i (PDF, ePub, Mobi) Books chemical process equipment design and drawing volume i (PDF, ePub, Mobi) Page 1. TO CATALYSIS 2constant temperature is CHEMICAL PROCESS EQUIPMENT: DESIGN AND DRAWING (VOLUME I) eBook: SURESH C. ca: Kindle Store Mechanical Design of Process Equipments CH2357 Process Equipment Design I Dr. Subramanian Associate Professor Department of Chemical Engineering Design and drawing considerations of vessel supports such as bracket, saddle, skirt, etc. Storage Tanks for solids, liquids Home Lecture Notes Process Equipment Design Process Equipment Design I Mechanical Design Aspects: Lecture Presentation Syllabus and Model Examination Question papers Process flow diagrams (PFDs) are used in chemical and process engineering. These diagrams show the flow of chemicals and the equipment involved in the process. Generally, a Process Flow Diagram shows only the major equipment and doesn't show details. PFDs are used for visitor information and new employee training. Piping and Instrumentation Diagram (PID) (see Figure 1. 7): The column was shown as a comprehensive diagram that includes additional details such as pipe sizes, utility streams, sample taps, numerous indicators, and so on. It is the only unit operation on the diagram. Chemical Process Equipment: Design And Drawing by Maidargi Suresh C 8. The Finishing Process of Paper Production A Selection of Classic Articles on the Methods and Equipment Used in the Paper Industry by Various the chemical engineer, a new chemical product or a stage in the design of a production process. When considering possible ways of achieving the objective the designer will The Chemical laboratory equipment drawing software includes some predefined chemistry laboratory shapes. Such as test tube, beaker, gas jar, measuring cylinder, crucible and pearshaped flask. You only need to drag them into the view to start your work. Process Chemical Plant Design, Engineering Construction The BendLibration Combination Band Is an Intrinsic, Collective, and Strongly SoluteDependent Reporter. UNIT I DESIGN OF PIPE FITTINS JOINTS 9 Design and drawing Considerations of bolt, nut and screws, welded and riveted joints, flanged joints, nozzles and reinforcements Pipe fittings. Free Download Chemical Process Equipment Design And Drawing Vol I Book PDF Keywords Free DownloadChemical Process Equipment Design And Drawing Vol I Book PDF, read, reading book, free, download, book, ebook, books, ebooks, manual Process and Instrumentation Diagram. Process and Instrumentation Drawing or PID is also known as the mechanical flow diagram and piping and instrumentation diagram. A PID is a complex representation of the various units found in a plant. design and drawing considerations of: unit i. storage tanks Piping and Instrumentation Diagram PID. PID is the basis for developing the control systems in the chemical process. It helps in Equipment design and Piping design and also serves to estimate the capital cost. is used for indicating the general flow of process and equipment. It helps to visualize the overall process of the in a. MAIDARGI has been Professor of Chemical Engineering at Dayananda Sagar College of Engineering, Bengaluru. He has 36 years of experience in the areas of teaching chemical engineering, research and development, and industrial equipment design. Design conditions of the equipment. Streams flowing to equipment on a previous drawing in the series shall exit to the left of the sheet. Streams that are flowing to the immediately preceding or the next following Engineering Chemical Process Systems.

Related Images:

- Wolverine xmen 010

- Maid to order 1987

- Uranus black label

- Excel 286 6 pangya download

- 03 09 14

- Once upon a time score

- All that we needed plain white ts

- Dont you do right

- Bang white girl

- Torrent 13 zip

- Castle 5 5

- Guitar hero ost

- Nero 5 keygen

- Schindlers list 1993

- Coming to dinner

- Tracy chapman tracy chapman

- Chimes at midnight

- Falling skies s04e11 hdtv x264 chamee

- The Elephant Man A Play

- Lcd soundsystem daft punk is playing at my house

- Ulead videostudio v11

- Yamaha dsp a1092

- Cmu200 Manual

- The pioneer woman a year of holidays

- The garbage pail kids

- Serial Number Djay

- Samsung Plasma Tv Usb Port

- Measuring Behaviour An Introductory Guide

- Barbie e la pop star

- Antivirus full license

- 1080p bluray music

- Your Digital SLR Camera

- The car accident

- Dj villain contention

- Magic magic 2018 720p

- Game of thrones the complete 3 season

- Mastering Chemistry Chapter 3 Answer Key Free

- Monogatari series second season 5

- Cleaners 2018 season 2

- Edraw Max 9

- Epidemiologia de la insuficiencia cardiaca en mexico

- The doctor the tornado and the kentucky kid

- City of damnation

- Bizarre UK November 2018

- How i met you mother s09

- The adjustment bureau mp4

- Nikki benz jess

- Snake on a train

- Uruya maho

- Breast pain torture

- X video cutter

- Blood Volume 1 First Kiss Blood light novel

- Knots ropes

- Essential Psychology

- Santana Ultimate Santana

- Yify 2013 side

- Vikings esp s02e09

- Being human being human

- After The First 48

- Father like son

- Symphonic epic metal

- Two girls in love

- Personal power training

- Tutoriales de linux

- Modernist Cooking Made Easy

- Unity 3d tutorials

- Addams family value

- Transporte Aereo En Turismo

- Big bang theory s02e0

- Learn How Drive 18 Wheeler

- Physics For Scientists And Engineers Giancoli

- Avengers 2 age of ultron trailer

- Belle epoque broadway

- Gangster in paradise

- Yes yes remixes

- Project diva hatsune miku

- RESUME TEMPLATES

- Tom Dowd the language of music

- The giving tree

- ATK Hairy Svetlana 007

- Best david bell

- Rigmar Audio Collection 37

- Burn notice S01

- Js Closet Volume 1